An easy-to-use, high-output inline filling system powered by precision conveyors—delivering big results in a compact footprint, customized to your entire production line.

Filling Pumps

Peristaltic + HighLo Series – One Machine, Any Viscosity

From water-thin tinctures to thick lotions, gels, and pastes, we fit the exact pump your product demands: ultra-clean peristaltic for shear-sensitive or pharmaceutical fills, and our proven HighLo (standard or XL) for heavy cosmetics, creams, and gallon-size runs. All pumps are servo-driven, fully recipe-controlled from the central HMI, and share the same quick-connect nozzles and 30 L+ waist-height stainless funnels for lightning-fast changeovers and zero waste. One conveyor line. Every liquid. Perfect accuracy every time.

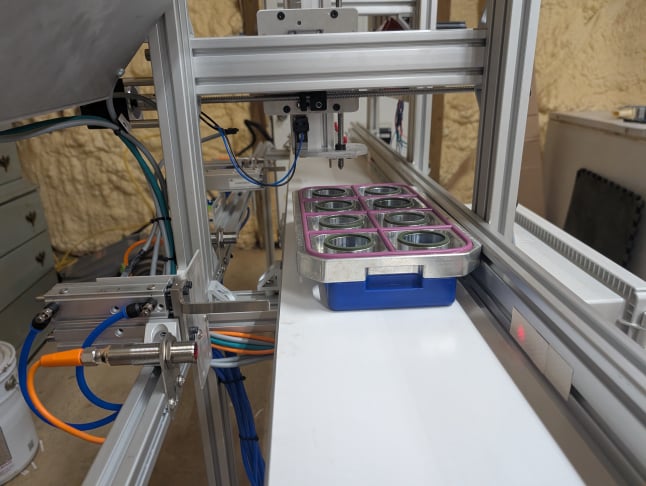

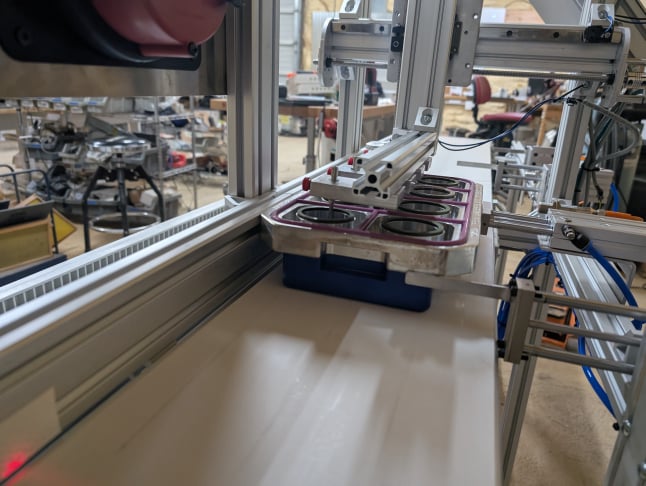

Servo-Guided Lid Placement & Press Station – Zero Touch, Perfect Seat

Lids are picked, oriented, and placed with pinpoint accuracy as bottles flow down the conveyor. Pneumatic or servo press head applies exact downward force for tamper-evident, flip-top, pump, or child-resistant caps – every lid seated straight, every time. 1 Tool changeover in under 2 minutes, fully controlled from the central HMI. Cuts labor, eliminates hand-fatigue, and runs flawlessly at full line speed.

One-Tool Quick-Change Chuck Torque Master – Any Cap, Any Bottle, Perfect Every Time

Single-tool chuck changes in under 60 seconds let you switch between flip-top, pump, trigger, child-resistant, disc-top, sport caps, and more — one station covers your entire product range. Servo-driven torque control applies exact, repeatable pressure with zero bottle damage or over-tightening. Fully automatic operation, seamlessly tied to the conveyor and central HMI. Fast, foolproof, and built for full-line speed.

Seamless 3rd-Party Labeler Add-On – Print & Apply or Pressure-Sensitive

Plug-and-play integration with industry-leading labelers (CTM, Weber, EPI, or your preferred brand). Bottles flow straight from filling → capping → sealing into the labeler with zero transfer gaps. Fully synchronized via the central HMI — start/stop, speed matching, and recipe selection all controlled from one screen. Front/back, wraparound, or print-&-apply — add perfect labels at full line speed without adding operators or floor space.

Full-Body or Tamper-Evident Sleeve Applicator – Shrink-Perfect, Every Bottle

High-speed inline sleeving station lays down full-body or neck-band tamper-evident sleeves at full conveyor speed. Steam or electric heat tunnel delivers wrinkle-free, 360° shrink with zero bottle distortion. Handles PET, HDPE, glass, and odd shapes. Sleeve changeovers in under 5 minutes, all parameters (speed, temperature, positioning) stored and recalled from the central HMI. Add eye-catching branding or unbreakable tamper evidence without slowing the line.

Inline Induction Seal Pro – 100 % Tamper-Evident, Zero Leaks

Fully integrated induction sealer activates foil-lined caps the moment bottles exit the capping station. Adjustable power for perfect seals on PE, PET, or glass — from 10 mm to 110 + mm diameters. Runs at full conveyor speed with no extra operator, no secondary station needed. Set it once on the central HMI and every bottle leaves leak-proof and tamper-proof, every shift, every day.

Multi-Liquid Layering & Blending

Each pump head can fill a different liquid into the same bottle simultaneously. Perfect for layered products, custom blends, or multi-phase formulations – all in one fast, accurate pass.

Multi-Liquid Layering & Blending

Each pump head can fill a different liquid into the same bottle simultaneously. Perfect for layered products, custom blends, or multi-phase formulations – all in one fast, accurate pass.

Bottomless Conveyor Coding Station – Crystal-Clear Date/Lot on Every Bottle

Dual-belt bottomless conveyor gently lifts and spins bottles over a high-speed inkjet (Videojet, Keyence, or your choice) or laser coder. Prints crisp lot codes, expiration dates, or 2D barcodes directly on the bottle base — no label needed. Fully synchronized with the main line speed and controlled from the central HMI; codes change automatically with each recipe. Zero slowdown, zero misprints, and works on round, square, or odd-shaped containers without any change parts.